![]() Mechanical Accuracy +/- 0.04 mm.

Mechanical Accuracy +/- 0.04 mm.

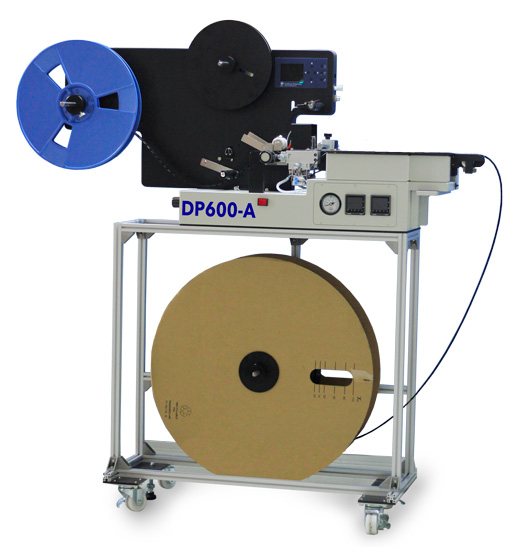

![]() Supported 22” input and output tape.

Supported 22” input and output tape.

![]() Supported 8~88 mm width cover tape.

Supported 8~88 mm width cover tape.

![]() RS232 interface,easily communicate with third party automatic system.

RS232 interface,easily communicate with third party automatic system.

![]() PSA (Press sensitive adhesive) and hot melt sealer.

PSA (Press sensitive adhesive) and hot melt sealer.

![]() CE Certificate.

CE Certificate.

DP600-A is a new generation Automatic taping machine which has already taken patents in several countries. Designed to be simple, easy operated; tape width adjustment can be finished within 10 seconds without any tool. DP600-A supports devices packaged in 8~88mm width tape. With advanced characteristics DP600-A offers the best solution for manufacturing process.

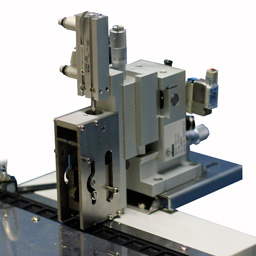

Cover Tape Sensor:The sensor will make alarm when run out of cover tape.

Empty Pocket Sensor:Check each pocket has carrier an IC.

Floating Chip Sensor:Check the floating IC.

SDP600-A is fitted with RS232/IO port for easy integration with most automatic system.

It has optional IC marker and CCD inspection devices thus allows DP600-A not only support automatic system integration but also help with production line’s quality assurance, marking and packaging procedures.

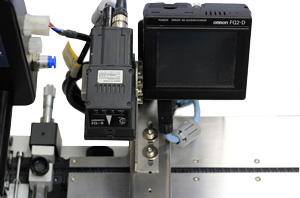

CCD Camera

Use CCD to check IC's outlook.

![]() Ink Marker

Ink Marker

Stemp dot,number or letter on the IC with different colors.

- 1 x DP600-A Main Unit

- 1 x System Stand

- 1 x User Manual

- Ink Marker

- CCD Camera